Alternative Cements | Compliance Beyond the Code

This article was featured in Structure Magazine, written by Mahmut Ekenel, Ph.D., P.E., FACI, ICC-ES Senior Staff Engineer

As the most widely used manufactured material on the globe, concrete is one of the materials that may be considered part of society’s foundation. Concrete can be a highly durable, resilient, and affordable material in the built environment, supporting sustainable, economic, and social development when properly proportioned. In addition, concrete can be molded into nearly any shape at the job site, bringing versatility to construction and making concrete a highly popular construction material.

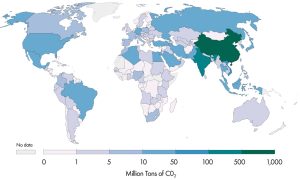

On average, over 4 billion metric tons of cement are produced yearly for concrete production. On the other hand, it is estimated that cement production is responsible for up to 8 percent of global greenhouse gas emissions among all such releases. A recent study showed that if the cement industry were a country, it would be the third-largest carbon dioxide emitter worldwide, topped only by the U.S. and China. Almost half of concrete’s CO2 emissions are created during the manufacture of cement clinker. Although energy demand in clinker production has been reduced over the last few decades, it is still the most-energy intensive part of the cement-making process. It requires heating a mixture of raw materials in a kiln to approximately 2642°F (1450°C) for modern portland cements. It is expected that future demand for concrete, fueled by population growth and the need for infrastructure rehabilitation and reconstruction, will continue to drive CO2 emissions from cement production higher.

Motivated to break this linkage, alternative cements (also known as non-portland cements) with reduced CO₂ emissions compared to traditional building code-compliant cements are being developed and increasingly utilized in concrete in recent years. One of the major incentives came from the State of California, the world’s fifth-largest economy. The state of California signed groundbreaking legislation in September 2021 to zero-out carbon pollution from cement in their state construction. Therefore, California is currently trying to establish interim targets for reducing cement’s greenhouse gas intensity and developing a strategy to achieve net-zero greenhouse gas emissions associated with cement used within California by 2045. It is speculated that California’s initiative may even likely influence cement production and use in the rest of the nation, opening doors wider for low-carbon alternative cements.

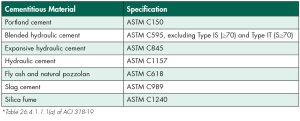

One of the concrete industry’s significant questions for the use of alternative cements is building code compliance of such cements, partly because most have proprietary formulations that may not comply with the building code requirements. Currently, the International Building Code (IBC), the predominant building code in the U.S. for new building construction, refers to the American Concrete Institute’s ACI 318-19, Building Code Requirements for Structural Concrete and Commentary, for code-specified cements, and does not contain provisions for alternative cements. ACI 318-19 has Section 26.4.1.1.1(a) for code-specified cements used in concrete (see Table). ACI 318-19 also has a new section that did not exist in prior editions (Section 26.4.1.1.1(b)) that allows the use of concrete made with alternative cements if they meet the performance requirements for the application, including “structural, fire, and durability.” Commentary to Section 26.4.1.1.1b refers to the ITG-10.1R guide, a report on alternative cements prepared by ACI Innovation Task Group 10. This report provides an extensive overview of alternative cements, case studies, and recommended testing methods. However, neither the code nor commentary of ACI 318-19 provides clear guidance about achieving building code compliance and acceptance conditions for evaluating structural, fire, and durability performance. Currently, ACI Committee 242 (Alternative Cements) is working on developing performance-based specifications for alternative cements, which may be considered for building code adoption in the future.

In addition, ASTM has published a standard for alternative cementitious materials, ASTM C1709 (Standard Guide for Evaluation of Alternative Supplementary Cementitious Materials (ASCM) for Use in Concrete). This standard has guidance with the intent of providing a technical approach to evaluating alternative supplementary cementitious materials such as pozzolans and hydraulic materials that fall outside the scope of code-specified standards such as ASTM C618, C989, and C1240. Although this standard provides good guidance, it does not cover all alternative cements, is not referenced by the building codes, and does not provide full building code compliance. ASTM also has active working committees developing specifications for non-hydraulic and special cements. These ASTM specifications may also be considered for building code adoption in the future.

Building Code Compliance

In the United States, a system of model building codes is adopted by local jurisdictions, which have the authority to enforce construction regulations. The IBC is the predominant building code used throughout the United States to establish minimum requirements for new building construction. The IBC has been adopted in all 50 states, the District of Columbia, Puerto Rico, and the U.S. Virgin Islands. Furthermore, several other countries/jurisdictions, such as Saudi Arabia, Pakistan, and Abu Dhabi, use the IBC as a reference code to develop their national building codes.

IBC Section 104.11 allows for the integration of new construction products, systems, and technologies not explicitly described in the code itself, permitting manufacturers to utilize their products if they demonstrate the products comply with the intent of the code. This demonstration is typically accomplished through product testing following established and peer-reviewed acceptance criteria documents. Acceptance criteria documents outline specific product sampling, testing, and quality requirements that must be fulfilled to verify that a product is code-compliant.

Today, the only building code provision for alternative cements is Section 26.4.1.1.1(b) of ACI 318-19, directly referenced by Chapter 19 of the IBC. As stated previously, this ACI 318 section allows the use of concrete made with alternative cement if it meets the performance requirements for the application, including “structural, fire and durability.” Therefore, the ICC Evaluation Service developed an acceptance criteria document for alternative cements (AC529) under IBC Section 104.11.1. Section 104.11.1 of the IBC states that supporting data, where necessary to assist in the approval of materials or assemblies not specifically provided for in the code, can consist of valid research reports from approved sources to demonstrate building code compliance verification usually issued following acceptance criteria. AC529 addresses the evaluation of alternative cements to comply with building code (IBC) objectives like structural strength, fire resistance, material properties, and durability. AC529 also outlines specific independent product sampling and quality requirements that must be fulfilled to obtain building code compliance verification. The evaluation results are summarized in a research (evaluation) report in accordance with Section 104.11.1 of the IBC and made available to code officials, registered design professionals, and the public.

Acceptance Criteria AC529

Acceptance criteria AC529, presented during an ICC Evaluation Service open public process and approved by an independent evaluation committee formed by selected code officials throughout the U.S., applies to low-carbon alternative cements activated by either water or a proprietary activator supplied by the manufacturer. Meeting these acceptance criteria is intended to demonstrate that a low-carbon alternative cement evaluated can be used in compliance with Section 26.4.1.1(b) of ACI 318-19 (as referenced by the 2021 IBC) or as an alternative to the cements outlined in Section 26.4.1.1 of ACI 318-14 (as referenced by the 2018 and 2015 IBC). The concrete produced using a low-carbon alternative cement can be used as structural and nonstructural, plain, or reinforced concrete provided the resulting concrete meets the design compressive strength and other specified engineering properties and durability requirements applicable for the end-use. This criteria for low-carbon alternative cements applies to concrete mixtures with normal-weight aggregates that comply with ASTM C33 or lightweight aggregates that meet the requirements of ASTM C330.

Acceptance criteria AC529 is titled as low-carbon alternative cement for use in concrete. Low-carbon alternative cement is defined as an inorganic cement (mostly with proprietary formulation) that can be used as a complete replacement for portland or blended hydraulic cements and is not covered by applicable specifications for portland or blended hydraulic cements. This replacement cement has a reduced embodied carbon relative to the code-compliant portland cement being replaced. Embodied carbon is a property expressed in kilograms of carbon dioxide equivalent (CO2e) per kilogram of product or material. Carbon dioxide equivalent is a unit of measurement based on the relative impact of a given gas (CO2) on global warming (the so-called global warming potential). Embodied carbon is usually measured from cradle to end of construction.

Although some local authorities/jurisdictions have already included mandatory cradle-to-end-of-construction embodied carbon assessments as part of their planning process, there currently is no industry-accepted standardized calculation method. Therefore, AC529 does not provide guidance for calculating embodied carbon and requires this information to be obtained from the manufacturer directly or from an environmental product declaration report from approved sources. In addition to reduced global greenhouse gas emissions, which yields reduced environmental impact, alternative cements may also offer improved performance over portland cement in some applications in terms of durability and strength.

The following sections summarize the evaluation of low-carbon alternative cement properties and their effects on concrete mechanical and durability properties in accordance with AC529. More detailed test and acceptance conditions can be viewed in AC529. Almost all mechanical and durability tests in AC529 require testing two concrete mixture designs with two representative compressive strength levels.

Cementitious Material Properties: Each low-carbon alternative cement formulation must be tested for standard physical requirements in accordance with the Table in ASTM C1157 for Type GU to identify and fingerprint the cementitious material properties for building code compliance. In addition, if there is any deviation in terms of heat of hydration (ASTM C1702) and time of setting (ASTM C191) that differs from the ASTM C1157 requirements, deviations are to be reported in the code-compliance research (evaluation) report.

Concrete Compressive Strength: The compressive strength test under AC529 aims to determine a benchmark for mechanical and durability tests of the criteria. All concrete mixture designs and cementitious material contents must be established to meet or exceed the minimum compressive strength requirement of 2,500 psi (17 MPa) in accordance with Section 19.2 of ACI 318-19. In addition, testing two compressive strength levels that differ by 3000 psi (20.7 MPa) is required for various other tests required in AC529.

Equilibrium Concrete Density: AC529 requires testing to be conducted in accordance with ASTM C567. The equilibrium density is reported and used in the modulus of elasticity calculations.

Concrete Splitting Tensile Strength: The test aims to evaluate the splitting tensile strength of concrete produced with low-carbon alternative cements. Tests are to be conducted in accordance with ASTM C496/496M. Average values must be higher than the value calculated by 6.7√f´c. The value of f´c used in this calculation must be the 28-day compressive strength in psi units obtained from the subsection above.

Concrete Modulus of Rupture: Flexural tests are to be conducted in accordance with ASTM C78/C78M. The average modulus of rupture of the three specimens must be higher than the calculated modulus of rupture value as required by ACI 318, Section 19.2.3.1. The value of f´c used for this equation is the 28-day compressive strength obtained from the subsection above.

Concrete Modulus of Elasticity: The test aims to evaluate whether low-carbon alternative cements used in a concrete mixture adversely affect the modulus of elasticity of the concrete. Tests must be conducted in accordance with ASTM C469/C469M. The average modulus of elasticity must not be lower than the calculated modulus of elasticity in accordance with ACI 318, Section 19.2.2.1. The value of f´c used for this equation shall be the 28-day compressive strength obtained from the subsection above.

Shrinkage and Volume Change: The test aims to evaluate the shrinkage cracking performance of concrete with low-carbon alternative cements. Tests are to be conducted in accordance with ASTM C157/C157M with a maximum 0.065 percent average strain measurements of all tests.

Freezing and Thawing Durability: This test aims to evaluate the durability of concrete subject to exposure to freezing and thawing conditions or deicing chemicals. Tests must be conducted in accordance with Procedure A of ASTM C666/C666M for a minimum of 300 cycles with a minimum durability factor of 80 percent.

Alkali-silica Reaction: Alkali-silica reactivity in concrete with low-carbon alternative cement formulations must be tested in accordance with ASTM C311/C311M and ASTM C1293, including some modifications given in AC529. Results must indicate that low-carbon alternative cement does not exacerbate alkali-silica reactivity if the 14-day expansion as a percent of control is a maximum of 100 percent. Alternatively, the low-carbon alternative cement does not exacerbate alkali-silica reactivity if the 12-month expansion in ASTM C1293 testing is a maximum of 0.04 percent.

Water Absorption: This test aims to evaluate the water absorption of the low-carbon alternative cement concrete mixture for durability and building envelope purposes. Tests are to be conducted in accordance with Procedure A of ASTM C1585 with a maximum water absorption of 8 percent.

Linear Coefficient of Thermal Expansion: The coefficient of thermal expansion of low-carbon alternative cement concrete must be reported by the testing laboratory in accordance with ASTM C531 and included in the code-compliance research (evaluation) report.

Chloride Content: The test aims to evaluate the chloride content of concrete with low-carbon alternative cements. Reports of tests in accordance with ASTM C1218 must demonstrate that each cementitious material concrete complies with Table 19.3.2.1 of ACI 318-19 for maximum water-soluble chloride ion content in concrete.

Sulfate Resistance: Sulfate resistance of the low-carbon alternative cement concrete is to be tested in accordance with ASTM C1012. The low-carbon alternative cement concrete is considered sulfate resistant if the average expansion after 6 months does not exceed 0.10 percent.

Fire-resistance: The purpose of the section is to evaluate the fire-resistance performance of concrete assemblies constructed with low-carbon alternative cements using either fire analyses in accordance with IBC Section 721 or testing concrete assemblies in accordance with ASTM C119 or UL 263. This evaluation may be omitted if low-carbon alternative cements in concrete are limited to non-fire-resistance rated construction assemblies in the published code-compliance research (evaluation) report.

Noncombustible Building Material: The purpose of this test is to demonstrate that concrete produced with the low-carbon alternative cements may be considered a noncombustible building material if the intent is to use in Type I, II, III, or IV construction per IBC Chapter 6.

Quality Control: To satisfy the quality objective of IBC Section 104.11, AC529 requires annual inspections of each manufacturing facility under an approved quality documentation for continuous production consistent with the material tested for qualification.

Summary

The IBC is the predominant U.S. building code. IBC Section 104.11 allows for alternative materials, designs, and methods provided that such alternatives have been evaluated to meet code requirements. AC529 provides the evaluation criteria and acceptance conditions for quantifying the use of alternative cements in compliance with ACI 318-19 or as an alternative to ACI 318-14. The final research (evaluation) report issued in accordance with AC529 is intended to demonstrate building code compliance. It is primarily used by code officials and registered structural engineers in charge of the construction.